- Joined

- Apr 23, 2021

- Messages

- 5

- Reaction score

- 0

- Country

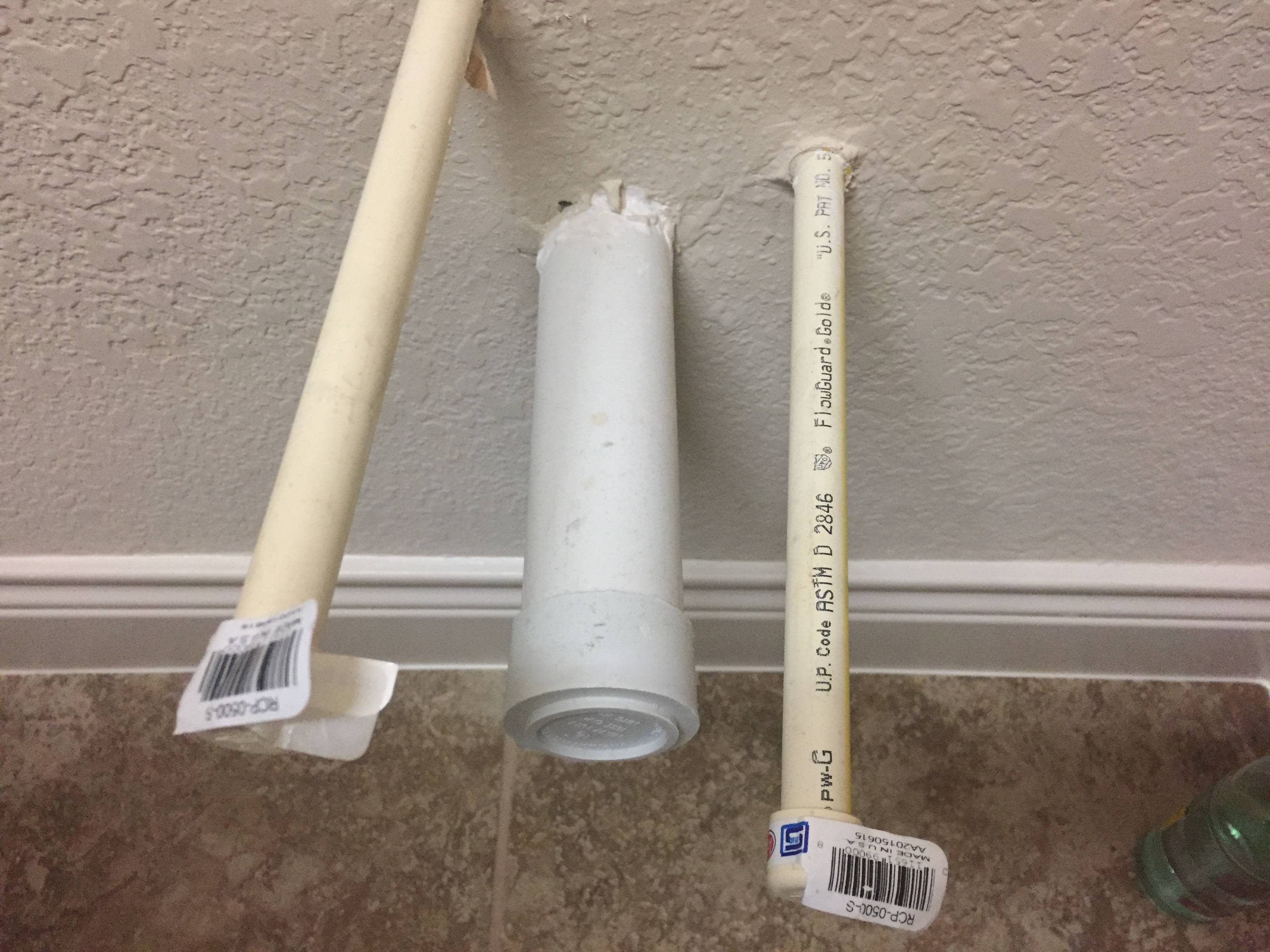

I am installing a stainless steel work sink. I researched as much as I could. Are these the parts and materials I need for this install? I have FlowGuard Gold, which is CPVC I believe. I believe the drain pipe is 1 1/2".

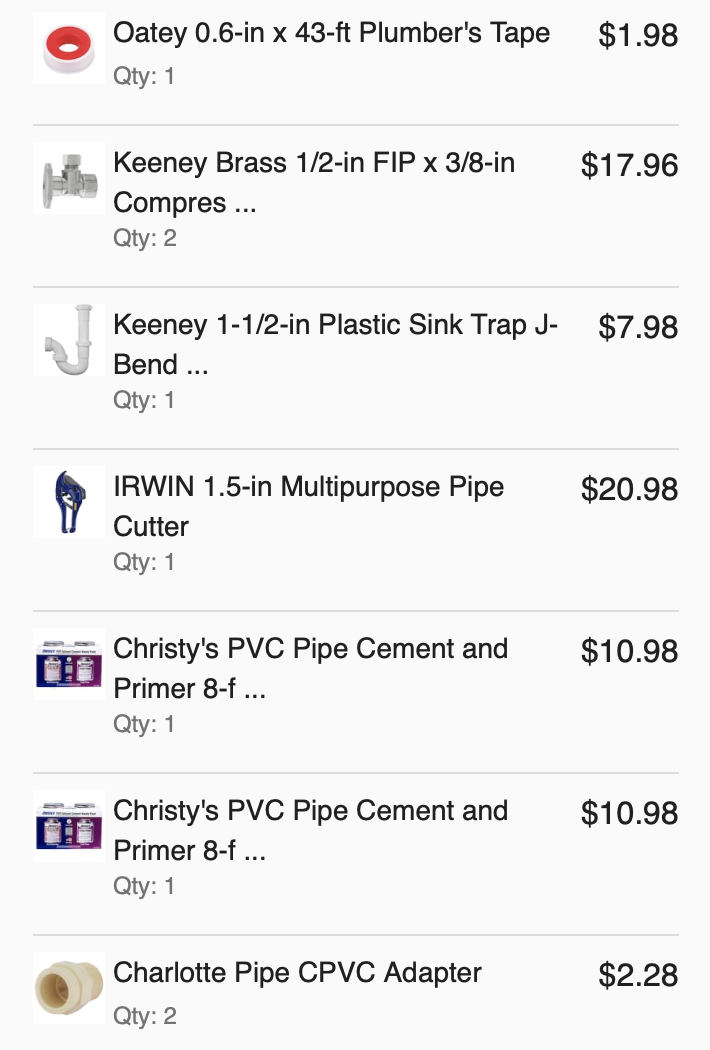

2 Keeney Brass 1/2-in FIP x 3/8-in Compression Quarter Turn Angle Valve

2 Charlotte Pipe CPVC Adapter

1 Christy's PVC Pipe Cement and Primer 8-fl oz PVC Cement and Primer

1 Oatey 0.6-in x 43-ft Plumber's Tape

1 Keeney 1-1/2-in Plastic Sink Trap J-Bend

1 Keeney Brass 1/2-in FIP x 3/8-in Compression Quarter Turn Angle Valve

1 IRWIN 1.5-in Multipurpose Pipe Cutter

1 Christy's PVC Pipe Cement and Primer 8-fl oz PVC Cement and Primer

1. Turn off water

2. turn on faucets to drain water

3. cut existing pipe

4. apply primer then apply glue and install adapters

This look like a solid plan to you guys? Anything I am missing?

2 Keeney Brass 1/2-in FIP x 3/8-in Compression Quarter Turn Angle Valve

2 Charlotte Pipe CPVC Adapter

1 Christy's PVC Pipe Cement and Primer 8-fl oz PVC Cement and Primer

1 Oatey 0.6-in x 43-ft Plumber's Tape

1 Keeney 1-1/2-in Plastic Sink Trap J-Bend

1 Keeney Brass 1/2-in FIP x 3/8-in Compression Quarter Turn Angle Valve

1 IRWIN 1.5-in Multipurpose Pipe Cutter

1 Christy's PVC Pipe Cement and Primer 8-fl oz PVC Cement and Primer

1. Turn off water

2. turn on faucets to drain water

3. cut existing pipe

4. apply primer then apply glue and install adapters

This look like a solid plan to you guys? Anything I am missing?