Cutting copper

- Thread starter Johnes

- Start date

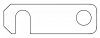

Hello, mainly we need to cut copper pieces 6x1,5x1 mm with holes for M6 bolt and round edges (I will attach rough sketch). Second thing that we need is 2x2x0,8 cm holes with round edges in Polypropylene. Lastly we would need to drill holes for M6 bolt in 4mm polycarbonate. We are looking for machine that could do such thing and doesn´t cost thousand of dollars. Can we buy something for around 1000$?

Attachments

-

28.9 KB Views: 119

Your most economical approach would be to find a metal shop that has a laser cutter or wire EDM. Many times high end trophy shops will have lasers that can do the job.

You could get a small CNC machine and see if that would give the finish you are after. You could try a cheap Chinese CNC machine from Aliexpress, but it would require a bit of experimentation. A local metal shop would give a much better finish though.

Johns’s, a cheap CNC mill can mill copper. There are several methods you could use to produce the part shown above. Depending on your estimated annual usage and for how many years you foresee making this part, I would investigate Laser to see if it is an economical choice. This part could also be made on progressive die quite economically if the quantity warrants. After seeing the part I would also suggest that you invest in a vibratory tumbler. You could deburr hundreds of parts and burnish them to a clean bright finish without touching them.

About 5000 pieces a year and we are making it for 10-12 year now... I saw that i woulf need to buy fiber laser because of the waves and because copper is quite reflective. Also i will need to work with plastic and iam not sure how well that works. Once we had progressive die but it didnt work very well for us. I will consider the vibratory tumbler but Im capable of deburring 100pieces in 1 hour so it doesnt seems to be worth of the investment.

Ask a Question

Want to reply to this thread or ask your own question?

You'll need to choose a username for the site, which only take a couple of moments. After that, you can post your question and our members will help you out.